Micro Silica is a very effective pozzolanic material. Standard specifications for micro silica used in cementitious mixtures are ASTM C1240, EN 13263.

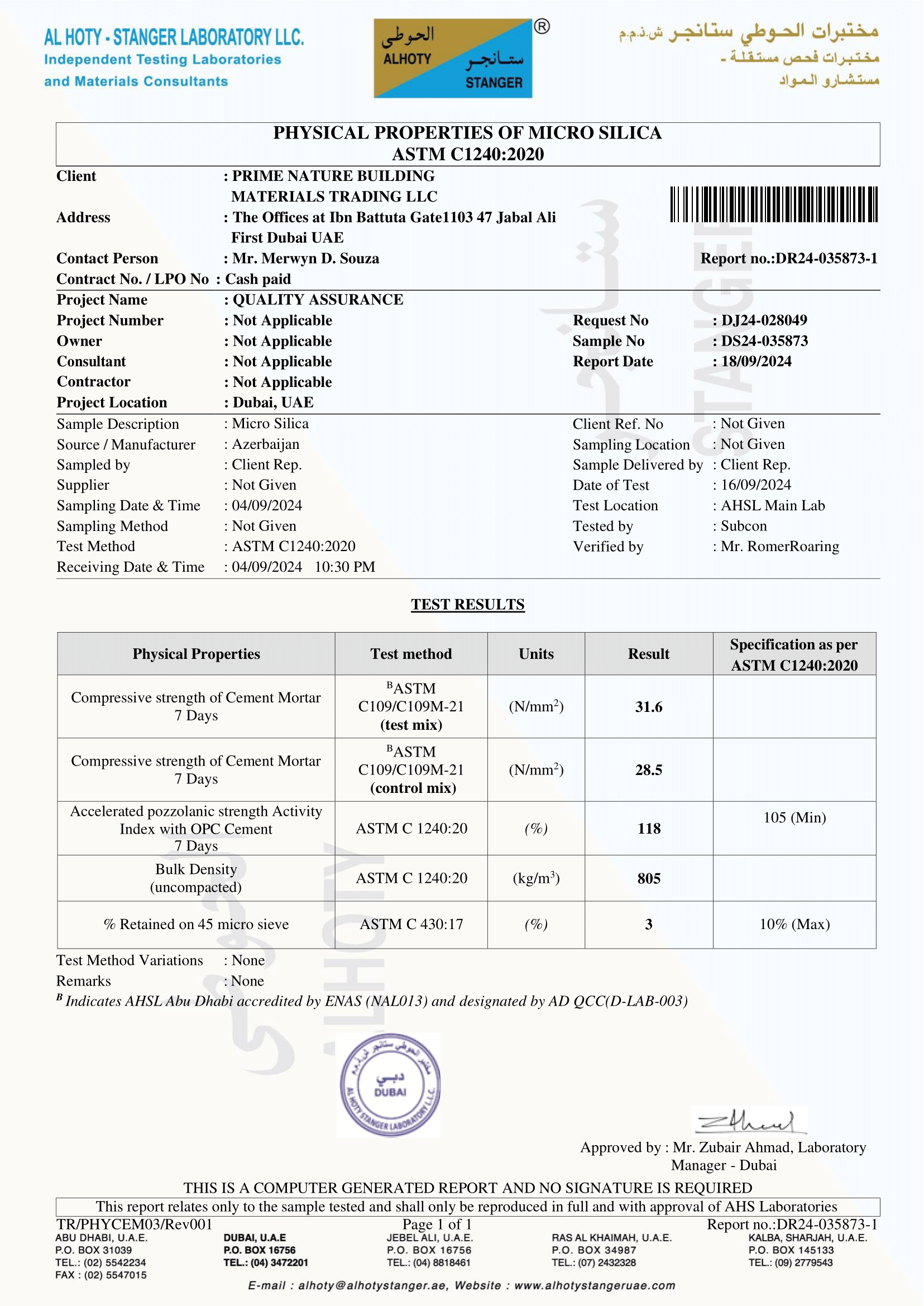

Micro Silica is added to Portland cement concrete to improve its properties, in particular its compressive strength, bond strength, and abrasion resistance.

These improvements stem from both the mechanical improvements resulting from addition of a very fine powder to the cement paste mix as well as from the pozzolanic reactions between the micro silica and free calcium hydroxide in the paste.

Addition of micro silica also reduces the permeability of concrete to chloride ions, which protects the reinforcing steel of concrete from corrosion, especially in chloride-rich environments such as coastal regions and those of humid continental roadways and runways and saltwater bridges.

Effects of micro silica on different properties of fresh and hardened concrete include:

Workability: With the addition of micro silica, the slump loss with time is directly proportional to increase in the micro silica content due to the introduction of large surface area in the concrete mix by its addition. Although the slump decreases, the mix remains highly cohesive.

Segregation and bleeding: Micro Silica reduce bleeding significantly because the free water is consumed in wetting of the large surface area of the micro silica and hence the free water left in the mix for bleeding also decreases. Micro Silica also blocks the pores in the fresh concrete so water within the concrete is not allowed to come to the surface.

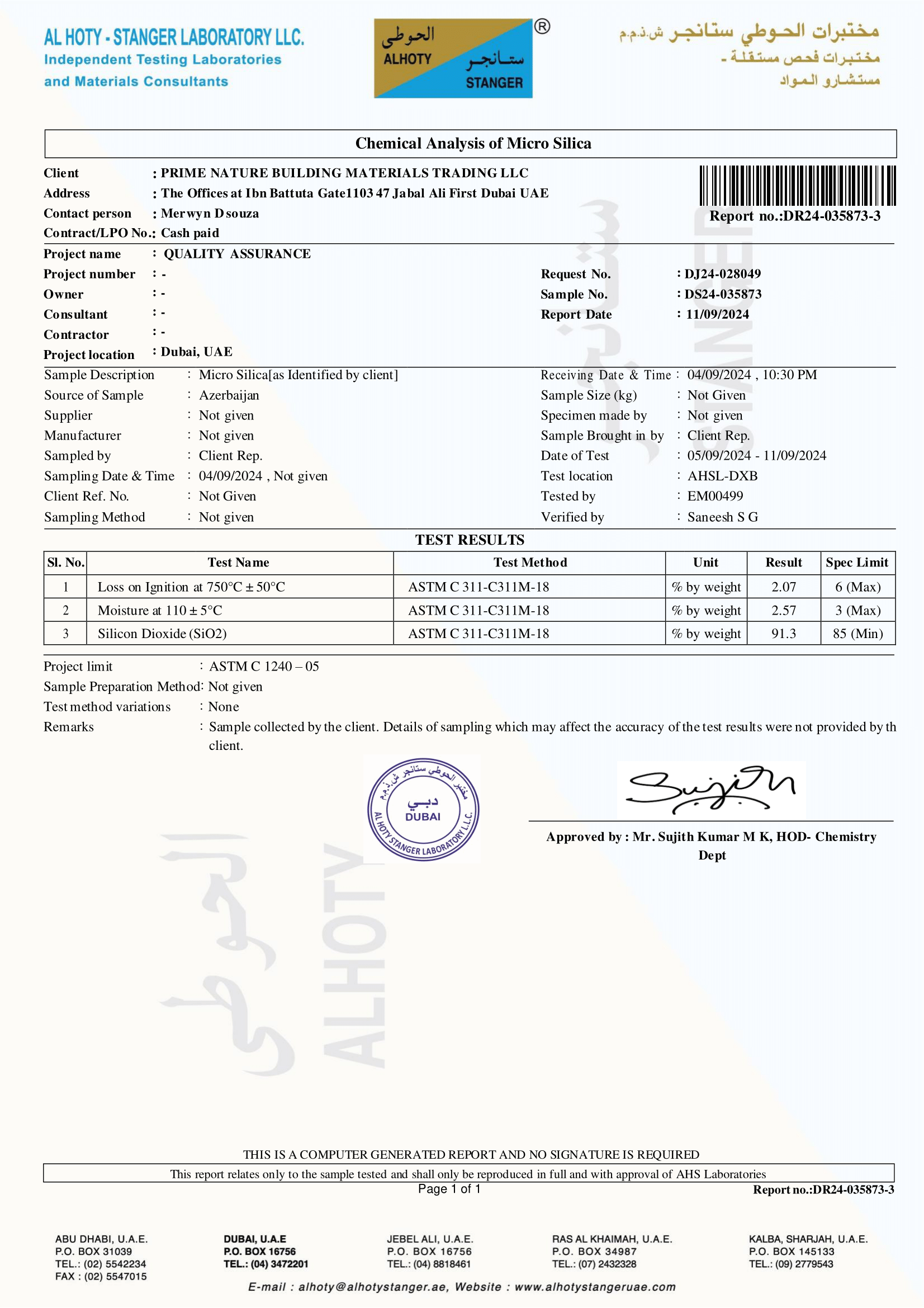

Microsilica, also known as silica fume, is an amorphous (non-crystalline) polymorph of silicon dioxide (SiO2). It is an ultrafine powder collected as a by-product of the silicon and ferrosilicon alloy production. Microsilica consists of spherical particles with an average diameter of 150 nm and a specific surface area of 15,000 to 30,000 m2/kg. Microsilica is highly reactive in cementitious and ceramic bond systems due to its high surface area and pozzolanic activity. Microsilica can improve the strength, durability, and workability of concrete and other materials. Microsilica is widely used in applications such as high-performance concrete, refractory, shotcrete, oil well cementing, and polymer composites.